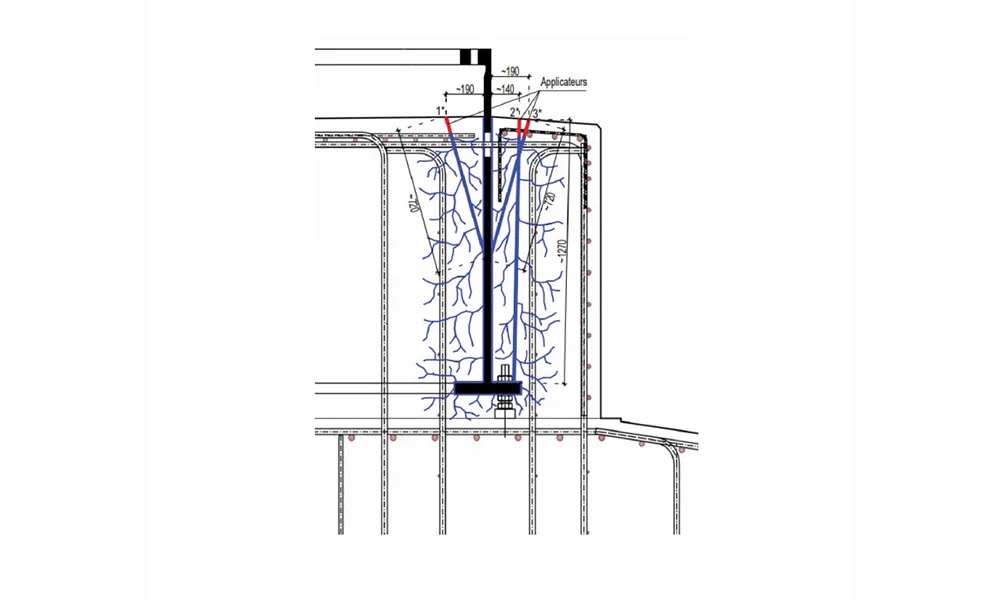

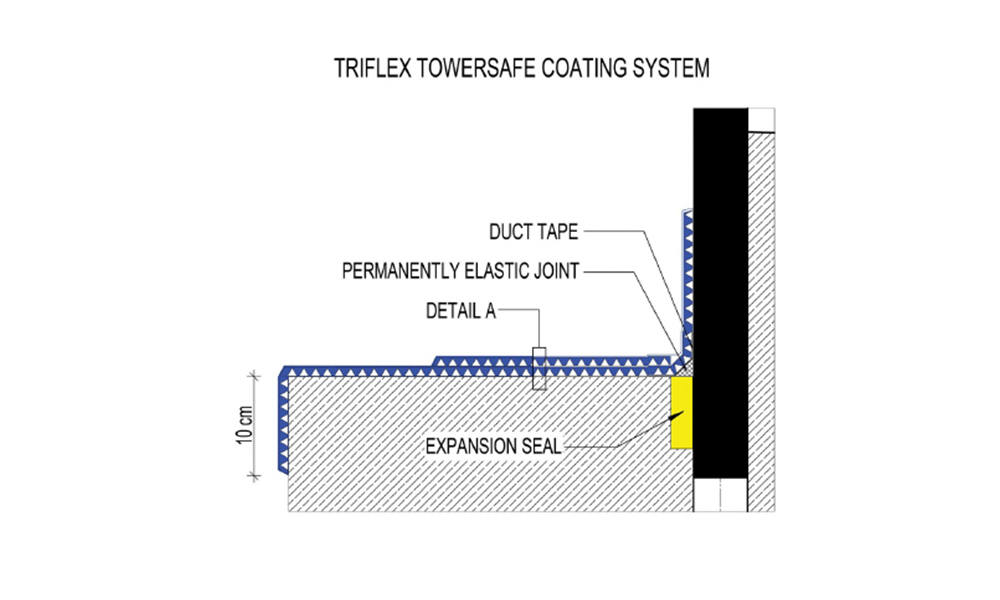

As leaders in the maintenance and repair of wind farm foundations, we offer a comprehensive range of services – from foundation surveys, to detailed diagnostics using state-of-the-art technology, to design

and budgeting for repairs, to the most advanced refurbishment work.

Our expertise in foundation design allows us to combine theory with practice and execution. As a result, we are able to uncover the real causes of failure and select optimal solutions, both in terms of cost and technology.

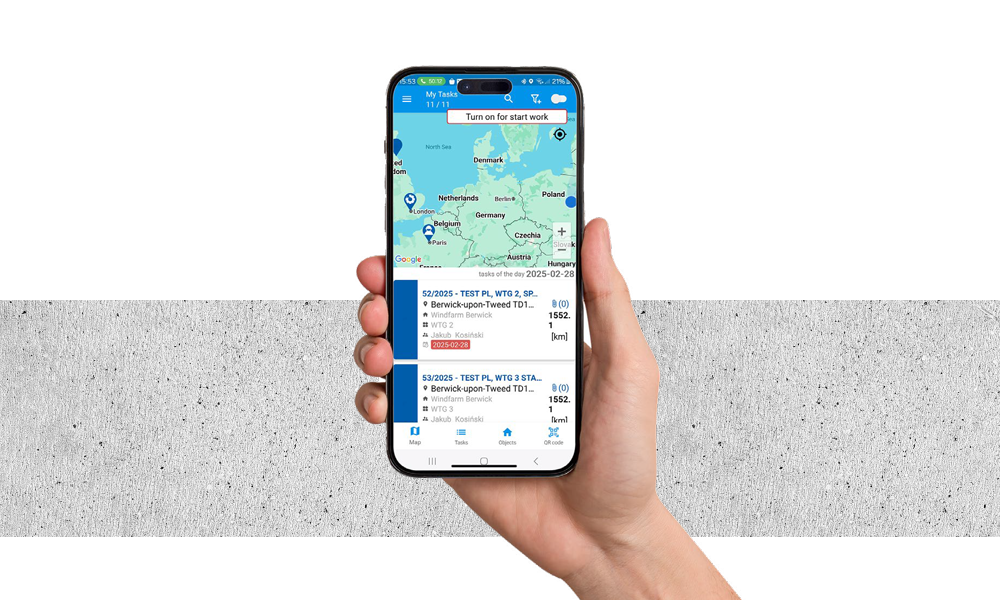

We periodically monitor the condition of several thousand foundations across Europe using the Wind Farm Foundation Standard (WFF), developed by foundation designers. We leverage advanced tools such as AI applications and algorithms. We offer the longest warranties, taking full responsibility for our expertise and repairs—past, present, and for the next 50 years

France

France

Poland

Poland

Romania

Romania

France

France