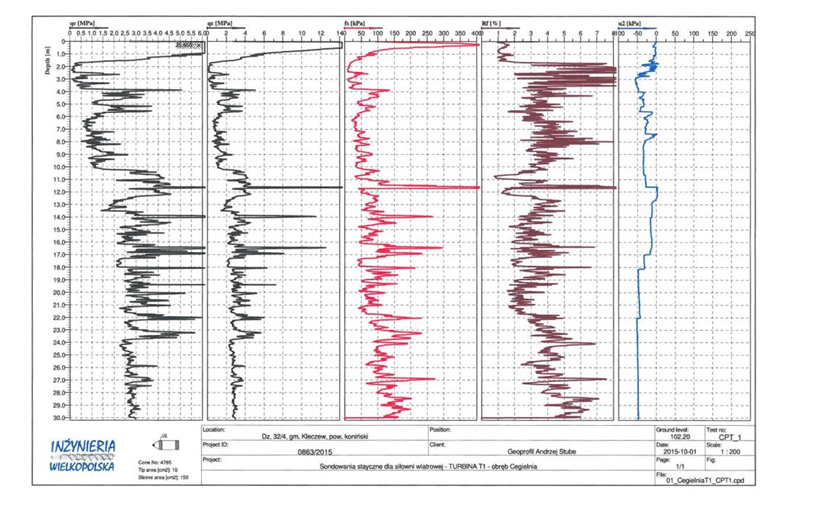

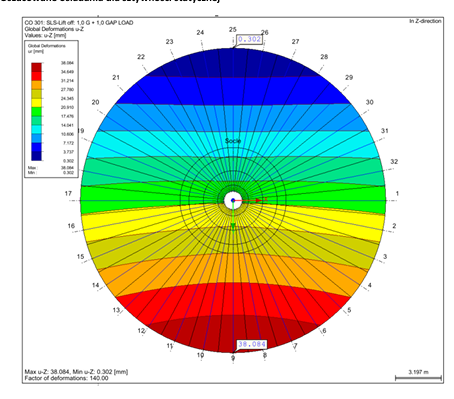

The design experience enables us to thoroughly supervise the entire foundation construction process, as well as to actively participate as a subcontractor in selected stages of implementation.

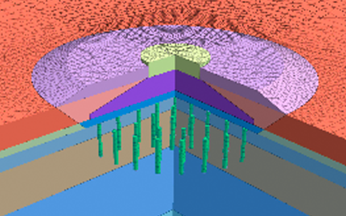

We work in all ground conditions and on different types of foundations. We use a wide range of technologies, including:

- CFA drilled-in columns

- CFA drilled piles

- CFA displacement piles

- FDC displacement columns

- Driven piles

- Micropiles

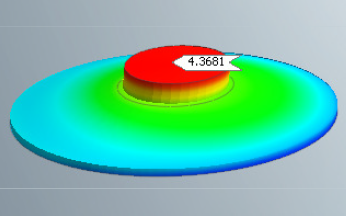

We do not tend towards any particular technology – we know their advantages and limitations and have a good understanding of the requirements of foundation projects. We select the optimum solution for each location to ensure the safety of the foundation and the profitability of the investment.

The foundation of our philosophy is quality, not quantity. We do not introduce unproven solutions and always look at constructions in the long term. This approach ensures that our partners are never surprised during the construction phase. We view the soil behaviour and foundation as a cohesive, integrated structure, and our experience in foundation design empowers us to develop better solutions. We take full responsibility for our projects—both now and for the next 50 years.

Poland

Poland

Brazil

Brazil

Ecuador

Ecuador

Georgia

Georgia

Serbia

Serbia

Lithuania

Lithuania